Objectives:

Investigation of erosion problem in nozzles of Pelton turbine

project Team:

Principal Investigator | Dr. Sailesh Chitrakar | KU |

Full Time Researcher | Mr. Aman Kapali | KU |

Part Time Researcher | Mr. Amul Ghimire | KU |

Project Date | September 2021 – February 2022 |

|

Summary

The sediment erosion problem is one of the operational challenges faced by hydropower plants established in the rivers originating from the Himalayas. Due to the large elevation difference in Nepal, the Pelton turbine is a good choice for installation. A variety of output powers can be achieved by varying the number of nozzles through appropriate sequencing. In addition to erosion problems caused by turbulence flow in the boundary layers, particle separation and collision with walls caused by accelerated flow, and vortex erosion resulting from sudden changes in flow direction caused by obstacles and flow diversion structures; these turbines are also susceptible to erosion problems.

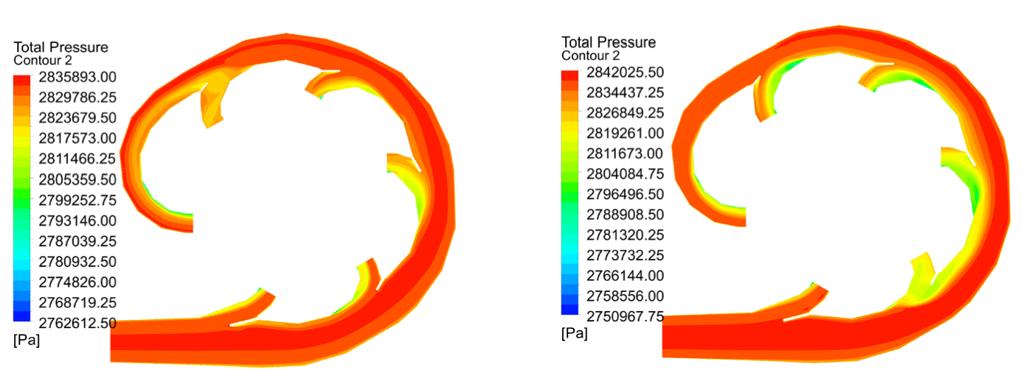

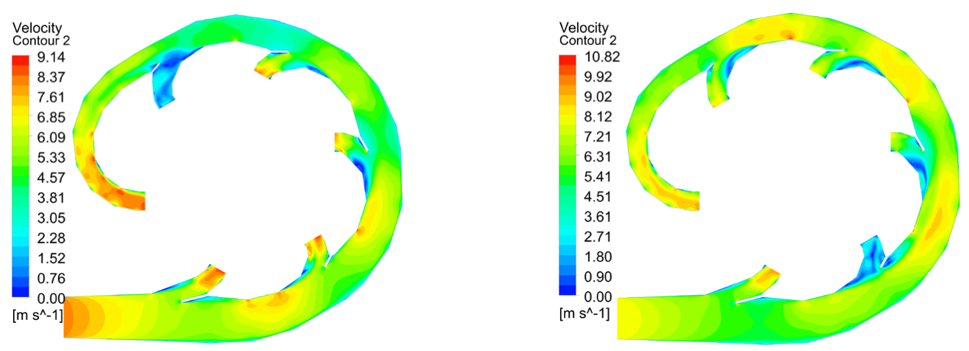

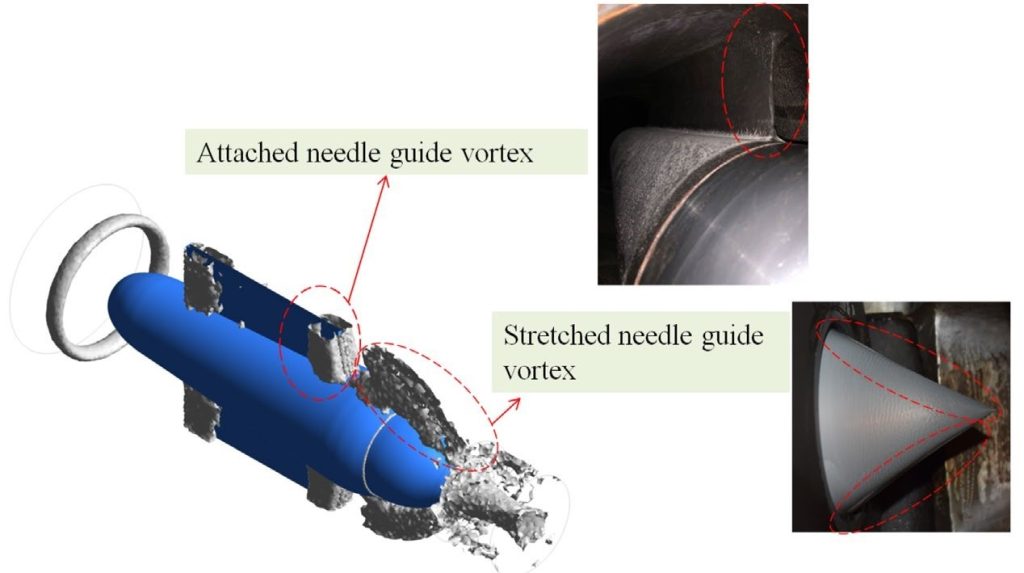

Bifurcations present in the distributing manifold produce the strongest separation vortices. Due to changes in flow direction, secondary flow vortices are generated at the bifurcations and elbows of the manifold, causing erosion in the boundary wall. Asymmetrical erosion along the needle length extending toward the needle tips can be caused by the needle guides supporting the spear valve forming vortices. The distribution system can be optimized to minimize erosion in Pelton turbines. From the first point of diversion, flow stagnation and recirculation can induct flow disturbances and head loss at subsequent points of bifurcation. In order to reduce its impact, the nozzle sequence should be designed so as to eliminate separation vortices.

The optimization of opening parameters of the turbine is also conducted from existing sequence A (1,3,4,5,6) to sequence B (1,2,3,4,6).