OBJECTIVES:

- Conduct a detailed hydrological study on the types of pumps needed for a selected region along with the market analysis.

- Design, fabrication, and installation of suitable pumps and required irrigation and drinking water supplies for the communities of the region.

project Team

Principal Investigator | Dr. Hari Prasad Neopane | KU |

Co-principal Investigator | Dr. Sailesh Chitrakar | KU |

Researcher | Mr. Nischal Pokharel Mr. Amul Ghimire Mr. Arun Pandey | KU |

Project Date | January 2022 to April 2023 | |

Funding Agency | Korea International Cooperation Agency (KOICA) |

Summary

The problems of irrigation in the hilly region of Nepal are very common due to the topography ever since the start of human settlement in the region. This is due to the height difference between farming land and water source. The available water source, like the river, flows below the cultivable land. Thus creating a barrier to the irrigation of the land. Among others, electrically or fuel-operated pumps are more popular due to their high pumping capacity. Besides their capacities, they also have certain drawbacks. In the case of rural hilly communities of Nepal, the lack of developed electricity supply facilities and also the high operating and maintenance cost of these pumps are some major drawbacks.

On the riverside farms, water-powered Coil pumps can be employed for pumping. This pump does not require any external sources of energy as it is operated by utilizing the power of river water.

This project is a continuation of the previous KU-IRDP project on the ‘Development of River Water Pump for drinking and irrigation purposes in rural areas.’ The pilot project consisted of the design, fabrication, and testing of the river water pump (coil pump) along with its application for drinking water supply after adding a water purifier. In some aspects such as improving the leakage problems, adding structural support and anchoring mechanism on the coil pump, conducting microbial studies on the bio-filter, etc., there are some research possibilities for the previous products.

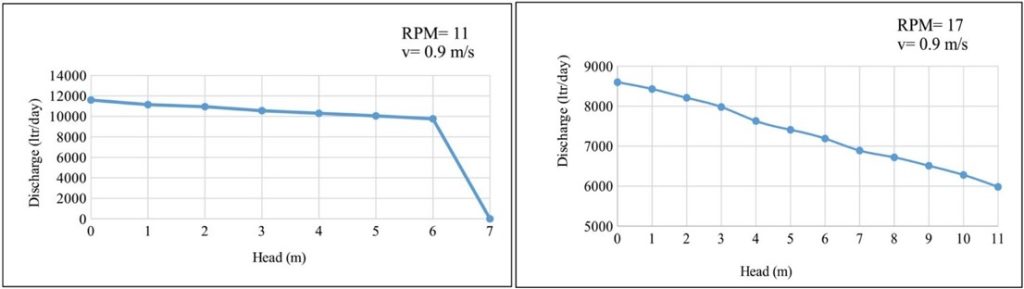

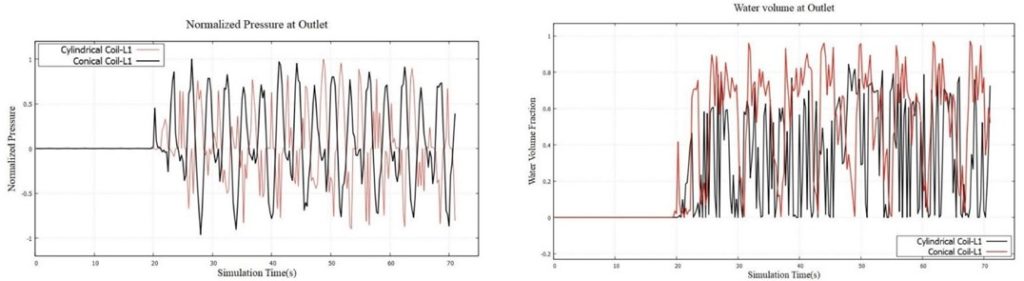

As a part of this project, research work has been carried out for two types of coil pumps i.e., cylindrical and conical coil pump and their performance were compared based on head and discharge. For this, both the conical and cylindrical coil pumps were designed, fabricated, and then tested in the Sunkoshi River, Nepalthok. In both cylindrical and conical-shaped pumps, it was found that the discharge of the pumps decreased as increasing lift. The maximum discharge was achieved by the conical pump i.e., 11500 liters per day, and the maximum head was achieved by the cylindrical pump i.e., 11 meters. The performance graphs of both pumps are shown below.