About TTL

Background and History

Kathmandu University (KU) conceived the idea of building a turbine testing facility in 1997 to support hydropower development in Nepal. The initial efforts to raise funds began with discussions with the Rural Energy Development Program (REDP) and the United Nations Development Program (UNDP), aiming to ensure the quality of micro-hydro turbines.

The lab was designed by KU faculty with support from the Norwegian University of Science and Technology (NTNU). NTNU’s Waterpower Laboratory, established in 1917 and modernized in 2001, served as a model, offering guidance throughout the initial design phase of TTL. From 2005, a series of discussions took place between the Norwegian Agency for Development Corporation (NORAD), KU, and Nepalese industries to establish a Turbine Testing Lab (TTL) in Nepal. In 2009, KU and NORAD signed an agreement for financial support for the construction of TTL. A total of USD 1.3 million was spent on constructing the lab, with NORAD funding 60%, Nepalese industries and institutes contributing 20%, and KU itself providing the remaining 20%.

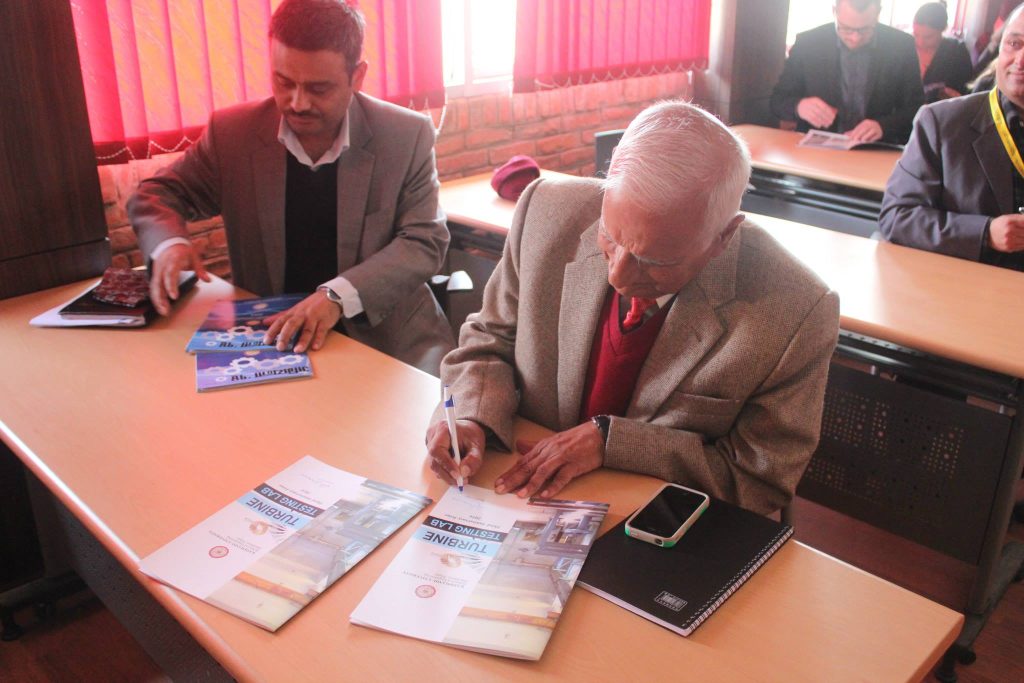

The lab was jointly inaugurated on November 10, 2011, by His Excellency Mr. Alf Arne Ramslien, Royal Norwegian Ambassador to Nepal, and Prof. Suresh Raj Sharma, Vice Chancellor of KU. KU established an independent Operation and Management Committee, including members from KU, the Institute of Engineering at Tribhuvan University, and a representative from local industries, to ensure the lab’s better utilization for education, research, and industrial purposes.

Design and Construction

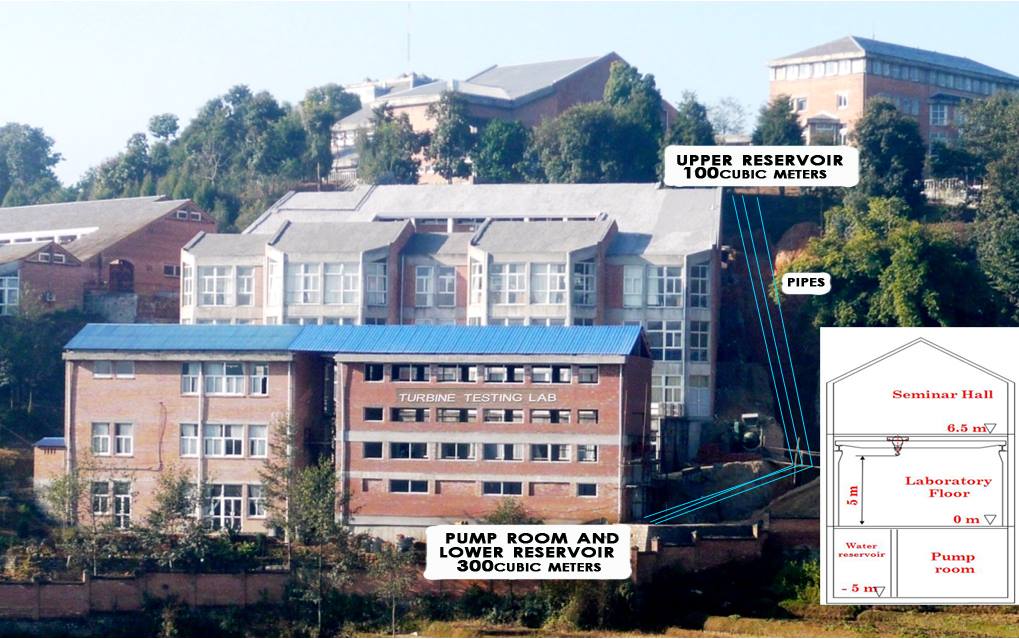

Civil works and hydro-mechanical works for TTL were carried out by Nepalese companies, Munna and Acharya Construction Co. Pvt Ltd, and Nepal Hydro and Electric Ltd. ITT Norge AS, a Norwegian company, supplied and installed the pump and control system for the lab. Throughout the construction phase, standard practices of quality control were implemented. Installations that did not pass the quality control tests were rebuilt.

Unique Features and Capabilities

TTL is the only lab in the world capable of performing tests with a 30 m natural head. The topography of KU’s location allowed for the placement of an upper reservoir to create this 30 m natural head. The lab is equipped with two centrifugal pumps, each of 250 kW, with variable frequency drives (VFD) for each pump.

Each pump can produce a maximum flow of 0.25 m³/s and a maximum head of 75 m. The pumps can be connected in series and parallel combinations, producing a maximum head of 150 m and a maximum flow of 0.5 m³/s, respectively.

Testing Capacity and Future Developments

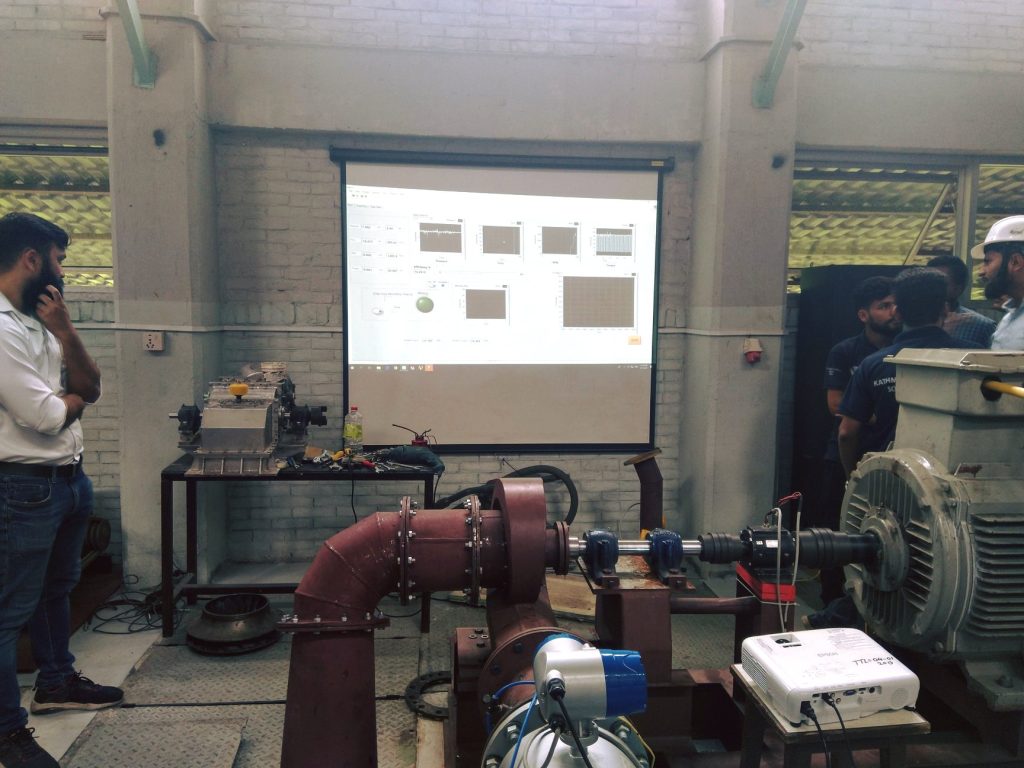

TTL has the capacity to perform prototype tests on turbines up to 300 kW and model tests for larger turbines. The lab has provisions for four test rigs at a time, along with notches and water volume measurement arrangements for calibrating measuring instruments. TTL also plans to incorporate state-of-the-art technologies such as Computational Fluid Dynamics (CFD) and Finite Element Method (FEM) analysis. Test rigs will be installed to perform tests on hydro-mechanical components.

Ongoing Collaboration and Training

TTL works in close cooperation with NTNU, Norway, which provides technical support and guidance for the lab’s further development. TTL also aims to offer specialized training to engineers and technicians to share the lab’s output and knowledge.

Purpose

1. Build competence and knowledge within the hydropower sector of Nepal

- Teaching/learning facility

- Industrial courses

- Staff training for the industry

2. Motivate research

- Development of efficient turbines able to withstand sand erosion.

- Development of turbine and pump technology

- Maintenance of Turbines

3. Provide a meeting place for the industry and university

- For research and student projects for the industry

- Collaborative research with national and international universities and research institutions